How to properly maintain FRP pipe products?

Overview:

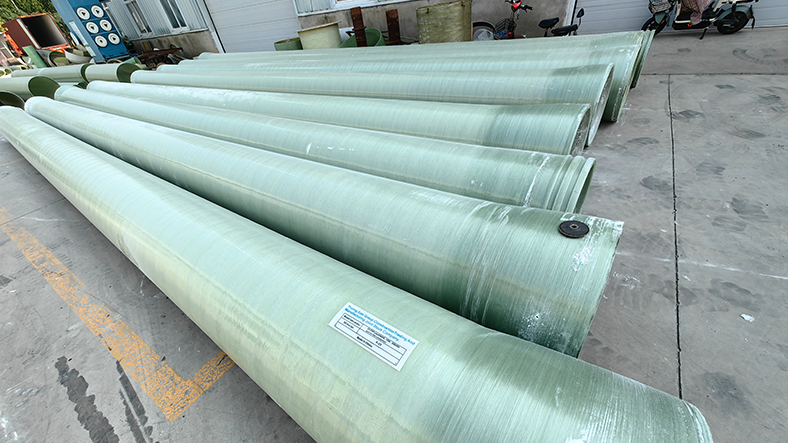

The inner surface of the glass fiber reinforced plastic pipe is very smooth and the friction resistance is small, which can obviously reduce the pressure loss along the way and increase the flow rate. In the case of the same flow rate, a smaller pipe diameter or a smaller power transfer pump can be selected, thus reducing the initial investment of the project and saving energy consumption (reducing the operating cost). Due to the addition of resin mortar in the middle layer of the pipe wall, the rigidity of the pipeline is greatly improved, and it is suitable for laying in various soil environments and seabed.

The inner surface of the glass fiber reinforced plastic pipe is very smooth and the friction resistance is small, which can obviously reduce the pressure loss along the way and increase the flow rate. In the case of the same flow rate, a smaller pipe diameter or a smaller power transfer pump can be selected, thus reducing the initial investment of the project and saving energy consumption (reducing the operating cost). Due to the addition of resin mortar in the middle layer of the pipe wall, the rigidity of the pipeline is greatly improved, and it is suitable for laying in various soil environments and seabed.

Here are several glass steel pipe maintenance methods:

1. Check the fixed condition of FRP

3. Check the operation of the use, access to historical maintenance records

3. Check and calibrate the mechanical running part

4. Check the electrical wiring

5. To check the surface condition

6. Check and adjust the overall operating conditions

7. Comprehensive and effective cleaning

Glass fiber reinforced plastic vertical storage tank

Previous Page:

Next page: